Custom Plastic Idler Pulleys, Rebar Chairs, Adapters, & Sprockets

USA-Made Plastic Products

After more than 40 years and with hundreds of different products made, Retlaw Industries has perfected its plastics manufacturing process. Along the way, we’ve developed our own line of high-quality, high-demand OEM components regularly manufactured in our 44,000 square foot facility. These products are designed by our CAD/CAM experts and are used by industry-leading manufacturers, like Husqvarna, Toro, and Exmark.

For these and many other manufacturers, Retlaw Industries has become synonymous with quality OEM parts. Consumer product manufacturers benefit from the inventory of plastic components at Retlaw, where exceptional is our standard. If you can’t find the correct size pulley, sprocket or adapter, or rebar chair on our website, contact us – if we don’t have what you are looking for on hand, we can design and build it.

Our line of exclusive OEM parts has improved consumer products in a range of industries, including:

- lawn and garden

- concrete

- fitness

- ...and any other industry with applications dependent on pulleys for operation

Our Products

Retlaw Industries produces high-quality thermoplastic products suitable for a wide variety of applications. Our inventory of components includes:

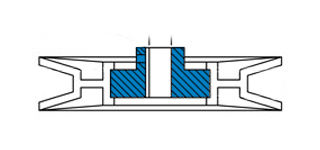

- Idler Pulleys – Simple mechanical devices used to control motion and transfer energy via belts, chains, rope or cables. Its mechanical advantage depends largely on its circumference.

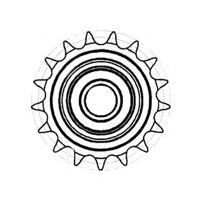

- Sprockets – mechanical devices used to impart a driving force on or control the motion of a belt or chain where slippage is unwanted. Unlike pulleys, the mechanical advantage lies both in its circumference and the ratio of teeth

- Adapters – inserts into the center of the pulley or sprocket and used as an intermediary between the rotating shaft and the pulley. Drive adapters transfer power from the shaft to the pulley

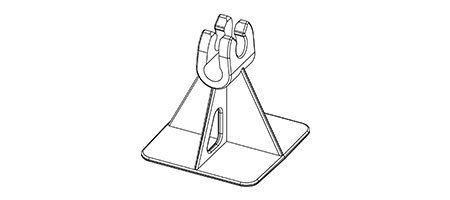

- Rebar Chairs - Rebar chairs are small supportive devices used in construction for reinforcing bars (rebar) in place at the correct height within concrete forms. Plastic rebar chairs resemble small stools or chairs.

Get a Quote on Retlaw's Plastic Products

Composite Thermoplastic Idler Pulleys

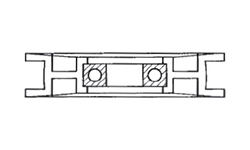

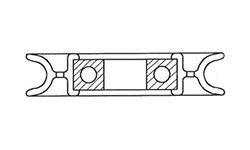

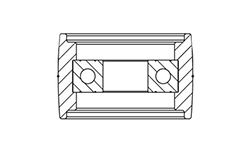

We produce dynamic and durable thermoplastic pulleys in a variety of styles to accommodate your needs. With the bearings molded in, our pulleys withstand high speeds and temperatures. Retlaw plastic pulleys have reduced surface friction and cause less belt wear than conventional pulleys. Our idlers don't corrode or suffer rivet fatigue because of the monolithic design encapsulating the bearing during the molding process.

Our idler pulleys come in an array of sizes and styles including:

- Flat – a common pulley with a uniformly flat center channel

- V-Belt – the center channel tapers inward for greater control over lateral belt shifting

- Round Belt – the curved channel is ideal for controlling the lateral shifting of round belts and ropes

- Cable – effective in use with steel cables, has a smaller channel radius than round belt idlers

- Flangeless – often used in conveyor belt applications, these idler pulleys have no central channel, hence the lack of a flange. Ideal for extremely stable, wide belts

Get Plastic Idler Pulleys at Retlaw

Power Transmission Roller Chain Sprockets

When your business needs new roller chain sprockets manufactured by a team of experts, Retlaw Industries is the way to go. Our plastic molding specialists produce low-power transmission sprockets resistant to most oils, solvents, chemicals, and corrosion. Retlaw sprockets come in a variety of sizes with anywhere from 19 to 12 teeth and fit chains sized #35, #40, #50, #60, and #80.

Plastic sprockets offer many advantages to industries that utilize them, including:

- Greater tooth deflection than on a metal sprocket, meaning plastic sprockets have a greater load capacity

- Less chain wear and quieter operation than metal sprockets

- Various plastic materials are available for roller chain sprockets based on your business's exact needs

- Fits a variety of shaft sizes due to our specialized idler adapters

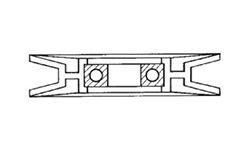

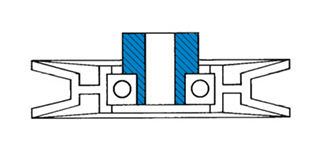

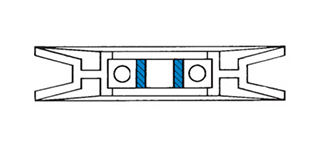

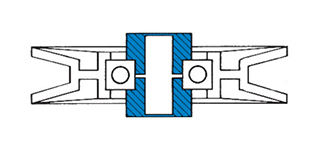

Idler Pulley Adapter Styles

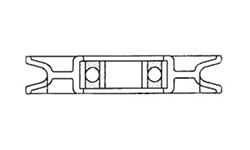

Pulley adapters, sometimes called bushings, change the compatibility of any given sprocket or pulley to fit the driveshaft on which it is applied. Proper application of our pulleys or sprockets is essential to their operation and reliability. With such a wide array of uses and styles, adapters are required to, well, help the pulley adapt.

Retlaw Industries stocks a wide range of sizes and several styles of adapters, including:

- Drive Adapters – these are built with an integrated key way to engage the rotation of the driveshaft and come with a 10-32 Nylock Set Screw to add wedging pressure

- Standard Bore Adapters – a common pulley adapter, these fit flush with the center of the pulley and provide no lateral separation on either side

- Shoulder Adapters – extend laterally on the shaft past the pulley bore, providing spacing on one side of the pulley

- Clevis Adapter – extends laterally on both sides of the bore, providing spacing on each side of the pulley

The types of adapters available are as wide-ranging as the types of pulleys and their uses. With the number of thermoplastic product combinations available, you’ll find the pulley system you need at Retlaw. If you don’t, we will work with you to come up with a practical and efficient plastic design to meet or surpass all of your expectations.

Get Mounting Adapters for Pulleys

Composite Thermoplastic Rebar Spacers

When your business manufactures construction equipment such as reinforced concrete steel bars, rebar chairs and spacers are a necessity. The experts at Retlaw produce precision-molded polyethylene chair clips to keep rebar in place during the concrete pouring process. These thermoplastic pieces are lightweight, easy to use, and inexpensive. They’re resistant to oils, solvents, and many acids and will replace the wire and concrete rebar chairs.

Retlaw Industries makes single and dual-direction rebar chairs in a range of heights, as well as dual-direction speed clips to accommodate different rebar gauges:

Custom-Designed Thermoplastic Parts for Your Industry

Not only idler pulleys and rebar chairs, but Retlaw Industries designs custom plastic parts for industries just like yours. Through our unique plastic injection molding process and high-quality assembly equipment, we can custom-make the parts your company needs for your particular application. We produce custom plastic parts for all types of industries, including:

- Lawn and garden care

- Fitness

- Automation

- Electronics

- Construction

- Appliances

- Agriculture

- Food Production

- Warehouses

- Transportation

- And much more

All of Retlaw’s thermoplastic components are lightweight, easy to use, and inexpensive to produce. The types of plastic we use are also resistant to oils, solvents, moisture, and many types of acids, and can often act as a more affordable replacement for metal and concrete components.

Place an order for the highest quality Idler Pulleys, Adapters, Sprockets, or Rebar Chairs at Retlaw.