What are Rebar Clips Used For?

Rebar chair clips, otherwise known as speed clips or rebar spacers, are used in place of cumbersome wire ties or welding to secure rebars together in walls, concrete flooring and more. The spacers are left in place for the pour to keep the reinforcement in place, becoming a permanent part of the building structure. Plastic rebar clips improve the strength of the concrete and have the advantage of low-cost production.

Rebar Connector Clips Speed up the Concrete Pouring Process

Secure Rebar with Thermoplastic Intersecting Clips by Retlaw Industries

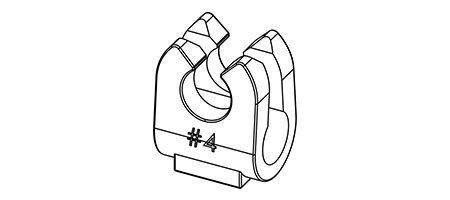

Rebar clips made by the plastic injection molding team at Retlaw reduce rebar setup time during your project’s concrete pouring process. Your steel fixers will thank you for eliminating the backbreaking work of wire-tying or welding rebar intersections.

Our plastic rebar clips connect intersections vertically or horizontally to maintain a steady rebar grid on which to pour concrete substrates. Quick-snap locking ensures your rebar grid will remain secure while keeping appropriate 90-degree angles for your structure.

Why Choose Retlaw for Plastic Rebar Chair Clips?

- Made from durable injection-molded polyethylene

- Rustproof material

- Resistant to oils, solvents and many acids

- Lightweight and low cost

- Accommodates rebar sizes #3, #4,#5, and #6

Retlaw Sizing Info

Retlaw Industries manufacturers several types of products. If you are interested in an adapter or idler pulley size that is not currently on our size chart, please contact us.

High-Quality Rebar Clips Manufactured for Your Industry

Since 1977, Retlaw Industries has manufactured molded plastic parts for countless businesses throughout the United States. Our dedication to our craft makes us the best at what we do, and we’ll help guide you through the injection molding process so you can be assured your part will meet specifications.

All our plastic molded parts are made in-house at our Wisconsin facility, ensuring your rebar clips will be manufactured by no one other than our injection molding team. Our standards for excellence and full accountability will ensure your product is made with world-class care.