Plastic Design & Engineering Company

Retlaw Industries: The Finest in Plastic Part Design for Injection Molding

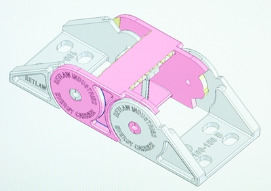

Whether you are building a birdhouse or making the best idler pulleys around, having a good design is paramount to the performance of the final product. At Retlaw Industries, we hire the best designers and engineers to work on our advanced Computer Assisted Design software, and it shows in the quality of our thermoplastic OEM parts.

Our in-house design lab is mere steps away from our machinists, allowing them to seamlessly integrate design into production.

Retlaw’s engineering technicians share in the responsibility for managing every phase of development and manufacturing. The experienced CAD/CAM design team at Retlaw works hard to bring you solid designs– the foundation on which your quality OEM part will be built – enabling both innovative and cost effective planning of tools, molding operations, and assembly. Not only will our technicians help conceptualize your design; they will advise which material will work best for your plastic product’s application.

Let Retlaw Help with Your OEM Part Design

Contact Retlaw's design team to take the first step in production of your custom OEM plastic part.

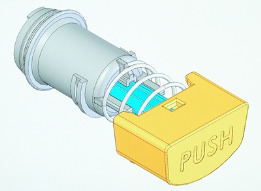

Hold it in your Hand: Rapid 3D Prototyping

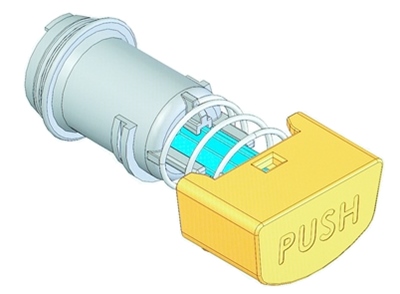

Whether you bring in advanced CAD drawings or just have a few doodles on a cocktail napkin, our plastic designing engineers will turn your concept into a reality. What’s more, using our ultra-modern 3D printer, we have the ability to produce fast prototypes so you can have a physical sample of your product before it goes into mass manufacturing in our on-site injection molding facility. You’ll be amazed how quickly the glimmer of an idea can become a tangible object.

Rigorous Design Concept Testing

Retlaw Industries’ designers strive for the validity of the concept. We place high expectations on our designers; they are the first and most important in defending quality manufacturing and maintaining cost efficiency for you. In order to maintain the highest level of scrutiny over design validity, they use the latest in product performance simulation software and testing programs.

Get Started on your Plastic Part Design

OEM Part Testing and CAM Equipment

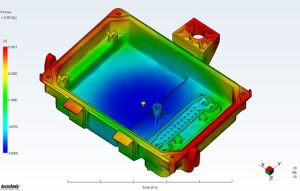

- Solidworks Premium Moldflow Software® – Offers a wide range of design testing simulations, from stress tests to electromagnetic induction heating simulations. Reduces cost by:

- Producing cooling quality, sink mark, plastic filling, molding window, and gate analyses

- Optimizing thickness of part walls to reduce raw material usage

- Assessing design manufacturing feasibility

- Identifying and helping to eliminate potential cosmetic flaws

- Accounting for OEM part orientation to maximize strength

- …and much more

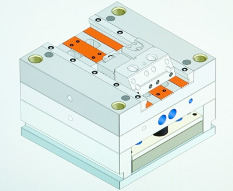

- PTC Creo Suite – A group of CAD applications used to design, share and analyze molds for injection plastics. This software allows users to determine the feasibility of mold design before it is sent off to one of Retlaw's tooling experts. The Creo Mold Analysis feature simulates injection molding processes to save time and money on reworking mold designs by discovering potential hidden problems before they are tooled into the mold. Helps determine and optimize injection locations to improve product aesthetics and shorten cycle times.

- Solidworks Premium 3D CAD Software® – This solid modeling software has been on CAD desktops the world over since 1995. It uses parametric features to create models and assemblies, keeping design intent specifics in mind as changes in dimensions are made. Retlaw’s injection molded parts designers benefit from its fluid flow and fatigue analysis features, stress testing capabilities, and even kinematic and dynamic motion analyses. Solidworks Premium 3D CAD Software® also streamlines workflow by learning and automating common tasks used in the design process. Our designers consider it an important ally in the war against inferior design.

CAM Programming Software at Retlaw

- Mastercam® Mill X5 – Mastercam has been supplying the CNC machining industry with high-quality CAM software since 1983, and is among the most widely used CAM software manufacturers worldwide. The versatility of Mill X5 gives our machinists and programmers the ability to effectively plan cutting strategies to minimize work time during the roughing process. An advanced hybrid style of cutting flawlessly integrates two separate cutting techniques into a single tool path to optimize machining times.

Resource Planning in CAD Design and Engineering

Design is just the first step in the process of producing our superior thermoplastic OEM parts. In order to present the best products possible to each of our clients in the shortest time possible, monitoring the process is crucial. To maximize efficiency, Retlaw employs resource-planning software to ensure manufacturing programs, execution systems, and workflow schedules are operating harmoniously for a leaner production facility.

Our efficient plastic molding design process is an integral part of our business model, and from our ERP software by IQMS to our all in-house production facility, Retlaw Industries will bring you the fastest plastics with the finest designs.

Retlaw Industries Serves Industries Across the United States

Retlaw Industries employs top designers and engineers to provide superior injection molding designs. We serve clients all over the United States, including Wisconsin, Washington, Pennsylvania, Ohio, New York, Minnesota, Michigan, Indiana, Illinois, Colorado, and more!

Our designers will make your plastic part idea take shape fast – Contact the CAD/CAM specialists at Retlaw today.