What is ULTEM 9085 Resin?

What is ULTEM 9085 Resin?

ULTEM 9085 resin is a brand name for Polyetherimide plastic (PEI). PEI was developed by Joseph Wirth in the 1980s. 9085 is a more durable thermoplastic that differs from other plastics due to its flame resistance, thermal conductivity, and overall strength. ULTEM 9085 is lighter than normal polyetherimide plastic, like ULTEM 1010. ULTEM 9085 has become the go-to material for aerospace, civil aircraft, and automobile manufacturing. On top of that, ULTEM 9085 is more affordable than other strong plastic alternatives like Polyaryletherketone (PAEK) or Polyetheretherketone (PEEK), but 9085 has a lower impact strength and usable temperature than these alternatives. Due to its amorphous nature, ULTEM 9085 does not have a constant melting point.

The professionals at Retlaw Industries use a wide variety of plastic materials for our injection molding processes, and one of the most versatile plastics we use is ULTEM’s PEI plastic.

Some of the benefits of polyetherimide plastic include:

- Heat resistance

- Stiffness

- Stability

- Environmental resistance

- Low smoke production

- Low flammability

ULTEM 9085 vs ULTEM 1010

SABIC produces a couple of different types of plastic under their ULTEM brand. Their two most popular types are ULTEM 9085 and ULTEM 1010.

ULTEM 9085 Pros:

- Heat Deflection Temperature (HDT) of 153ºC

- Strength rating of 6800 psi (pounds per square inch)

- Flexural strength rating of 16,200 psi

- Better choice for panels, tools, jigs, fixtures, and any application that benefits from lighter materials.

ULTEM 1010 Pros:

- HDT rating of 216ºC

- Strength rating of 9300 psi

- Better choice for power tools and equipment that withstands high temperature due to a lower thermal expansion rating than ULTEM 9085

ULTEM 9085’s strengths far outweigh its weaknesses, which is why many industries all over the world use it for heavy manufacturing.

The Benefits of ULTEM 9085 Plastic in Everyday Life

Since the 1980s, corporations like GE have used ULTEM™ in many different plastic applications. Today, ULTEM 9085 is one of the most common plastics used for industrial and manufacturing purposes. Common applications for ULTEM 9085™ include:

- Aerospace manufacturing for aircraft and spacecraft

- Automobile manufacturing

- 3D Printing education in schools

- Medical tools and equipment

- And many more commercial products

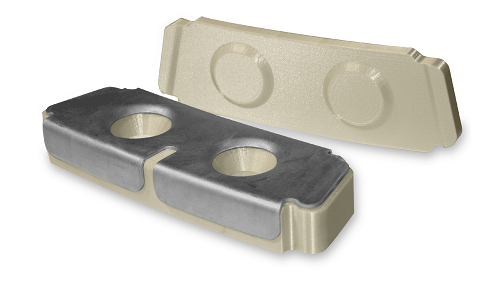

When your business needs high-quality idler pulleys, adapters, rebar chairs, sprockets, or custom parts manufactured using ULTEM 9085 or any other PEI brand, Retlaw Industries is the way to go. We provide businesses all over the United States with the best injection molded parts at the most affordable prices. Injection molding is faster and more cost-effective than 3D printing when used for mass production.