Composite Plastic Molded Part Assembly

Retlaw Provides Plastic Part Assembly

Retlaw Industries is your full-service producer of high quality thermoplastic parts. This means from the design to the creation, we are fully dedicated to the completion of your OEM subsystem. Since many injection-molded pieces require some assembly to become a complete part, we have gathered an experienced crew of part assemblers to work in our fully equipped assembly room.

The assembly room at Retlaw is located in the same 44,000 ft² facility as the molding area, the tooling section, and the design lab. This eliminates transporting parts to different facilities for assembly, allowing us to provide quality assembled thermoplastic OEM components at the most competitive pricing.

Efficient Equipment, Improved Plastic Products

Having the best assembly equipment is absolutely essential to striking a balance between the quality and fast turnaround our clients associate with Retlaw. We train our assembly technicians to be completely familiar with all related equipment, so they can efficiently produce quality assemblies.

Our spacious and fully-equipped part assembly workstations allow our workers to partially or fully assemble your plastics to fulfill your company’s OEM part needs. You'll get your products to the end consumer quicker.

Contact Retlaw for Fully Assembled OEM Parts

Retlaw will assemble your custom OEM thermoplastic products – Contact the plastic masters today!

Retlaw Plastic Assembly Equipment and Tools

Ultrasonic Welding, Hot Stamp, and Pad Printing

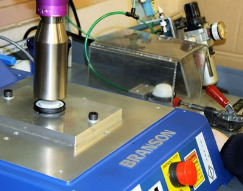

Ultrasonic Plastic welding machines produce a molecular bond between compatible thermoplastic parts. This bond is superior in production time and strength to both chemical and mechanical bonding.

Plastic Assembly

- Dukane Ultrasonic Welders – Ultrasonic welders align two compatible components on a fixture and a titanium piston-like fixture is rested on the top component. Next, as with any plastic welding procedure, pressure is applied to the piece. The fixture then vibrates ultrasonically between 20 kHz and 40 kHz to produce intense friction, which bonds the two pieces of molecules. The parts then undergo a hold time to hermetically bond them.

Plastic Printing

- Kensol-Olsenmark Hot Stamps – Hot stamp machines are used to print or lettering, part numbers, logos, and other markings onto your thermoplastic component. We use 3, 5, and 7-ton versions to accommodate a wide variety of projects.

- Pad Printing Machines – Using a process sometimes referred to as tampography – which still has its roots in the earliest printing technology – our printers apply ink-based two-dimensional images onto assembled parts. Retlaw’s pad printers have platens in two sizes: 6x10 and 4x8.

Time-Saving Assembly

You want to get your product out to customers as fast as possible; time is most definitely money. If you need thermoplastic components requiring some assembly, there’s no need to ship them piecemeal to be assembled at your facility. Retlaw Industries has the expertise in thermoplastic OEM part production and assembly to save you time and additional shipping costs by completing your assembled part in-house. It’s all part of our commitment to bringing you the finest plastic products possible.

Don’t hire additional assemblers for your OEM subsystem needs – Contact the plastic part assembly pros at Retlaw.