Plastic Injection Molding vs 3D Printing in Wisconsin

Which is Better for Manufacturing Plastic Parts?

For bulk applications, injection molds are generally favored over 3D printing. Plastic injection molding and 3D plastic printing sound very similar – both processes use CNC machines to mold, shape, and design plastic components into a particular shape for a specific purpose.

For bulk applications, injection molds are generally favored over 3D printing. Plastic injection molding and 3D plastic printing sound very similar – both processes use CNC machines to mold, shape, and design plastic components into a particular shape for a specific purpose.

So what are the main differences between plastic injection molding and 3D printing, and which one would you want for your business?

Get Plastic Injection Molding Help

| Injection Molding | 3D Printing |

|---|---|

Injection Molding Process

|

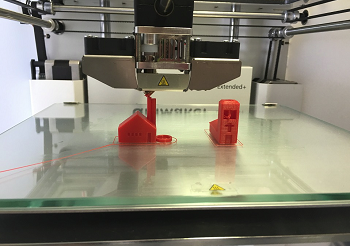

3D Printing Process

|

Injection Molding Production Time

|

3D Printing Production Time

|

|

Cost of Injection Molding

|

Cost of 3D Printing

|

Is 3D Printing or Injection Molding Better?

If you need to mass-produce plastic parts or components in bulk for industrial applications, plastic injection molding services from manufacturers like Retlaw Industries are what you need. However, if you want to save money and only need a limited amount of plastic parts, 3D plastic printing may be the solution best fit for your case.

Plastic molding methods continue to advance day by day, and better technology for both plastic injection molding and 3D printing continues to develop from industry professionals. Plastic injection molding is becoming more and more affordable for businesses in need of thermoplastic part production, and 3D printing continues to innovate with better, more versatile machines for faster turnover times.

If you want information about plastic components for your industry, call the experts at Retlaw today to learn more

Types of Plastics

- Polystyrene (PS)

- Polypropylene (PP)

- Polyoxymethylene (POM)

- Polyetherimide (PEI)

- Polycarbonate (PC)

- HDPE (High-Density Polyethylene)

- Nylon (PA)

- Acrylic (PMMA)